Some heat exchangers are designed to handle the common thermal management needs of companies in most modern industries. The streamlined way in which they prevent electrical overheating can be adapted to handle most electrical cooling needs with optimal efficiency and productivity. Some heat exchanger designs, however, are made specifically to handle some of the more unique and demanding needs of today’s more modern industrial applications. Modern cold plates are a type of heat exchanger that can provide the same highly efficient thermal management solutions that heat exchangers have always been known for. Yet, they can typically handle larger amounts of waste heat at a time, and over larger individual surface areas.

Some heat exchangers are designed to handle the common thermal management needs of companies in most modern industries. The streamlined way in which they prevent electrical overheating can be adapted to handle most electrical cooling needs with optimal efficiency and productivity. Some heat exchanger designs, however, are made specifically to handle some of the more unique and demanding needs of today’s more modern industrial applications. Modern cold plates are a type of heat exchanger that can provide the same highly efficient thermal management solutions that heat exchangers have always been known for. Yet, they can typically handle larger amounts of waste heat at a time, and over larger individual surface areas.

The advanced cooling methods of cold plates

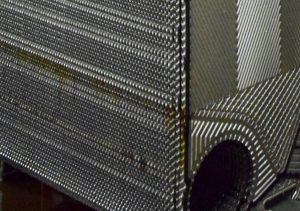

Cold plates operate on the same principles of transferring electrical waste heat that traditional heat exchangers do. Within the cold plates, an eco-friendly cooling fluid flows through custom-machined pathways that lead away from an application’s heat source. The metal cold plates can absorb heat at any point on their surfaces, and through a process known as conduction, transfer that heat to the cooling fluid flowing within them. The heated, less dense fluid flows quickly away from sensitive components to prevent the heat from damaging them, then releases the heat when it reaches the heat sink or other depository.

More energy efficient cooling solutions

Combining natural, highly efficient heat transfer methods is a large part of what makes cold plate heat exchangers effective at high-performance thermal management. It’s also an important foundation for the many different benefits that cold plate heat exchangers provide to modern industries. For instance, compared to traditional electrical cooling solutions that relied on air conditioning or air compression methods, cold plate heat exchangers can produce optimal results with minimal amounts of energy. Naturally transferring heat doesn’t require the use of chilled air or complicated forced convection equipment to be successful, which minimizes the need for energy to power the advanced cooling units.

The customizable nature of cold plates

The ability to utilize more natural cooling methods makes cold plates more than just energy efficient. Another important advantage is the ability to facilitate these cooling methods in a wide variety of cold plate designs. As with other heat exchangers, cold plates can be custom-designed to meet each application’s unique thermal management needs with optimal results. The ability to stack multiple cold plates together to enhance a heat exchangers’ cooling capabilities allows companies to utilize higher-performance solutions within minimal spaces. For more information about how cold plates became high-performance electrical cooling solutions, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.