In the realm of food and beverage production, thermal management concerns span a wider range than in many other industries. For instance, the electrical thermal management needed to keep technology and equipment properly cooled is similar to the needs of nearly every other industry. However, other processes specific to food and beverage production also rely heavily on effective thermal management, and with advanced heat exchangers, companies can streamline those processes, as well.

In the realm of food and beverage production, thermal management concerns span a wider range than in many other industries. For instance, the electrical thermal management needed to keep technology and equipment properly cooled is similar to the needs of nearly every other industry. However, other processes specific to food and beverage production also rely heavily on effective thermal management, and with advanced heat exchangers, companies can streamline those processes, as well.

Applications for Advanced Thermal Management

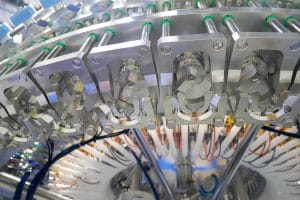

The advent of technology such as automated machinery and equipment has transformed manufacturing of all types. That technology requires innovative thermal management capabilities that can keep up with heightened outputs of electrical waste heat. However, food and beverage production also includes thermal management in the form of applying heat to facilitate processes such as pasteurization, and consistent below-ambient cooling to keep products safe for consumption. In most of these applications, heat exchangers provide companies with the high-performance,

The Advantages of Using Heat Exchangers

In common applications, such as cooling electrical enclosures and control panels, heat exchangers are well-known for their ability to transfer waste heat before it causes any damage to sensitive components. Below-ambient heat exchangers can provide equally reliable cooling for safer storage, packaging, and shipping at a lower cost than most other alternatives. In applications where heat must be applied and sustained, heat exchangers can be utilized to transfer the electrical waste heat they collect so companies can utilize it as necessary.

How Companies Benefit Overall

The benefits of streamlining electrical thermal management are many, and include reducing overall costs and energy consumption, as well as allowing essential equipment to run continuously. The benefits to food and beverage companies are even more pronounced when heat exchangers are used for other applicable processes, as well. For example, the use of electrical waste heat to facilitate processes like pasteurization helps companies reduce or eliminate their reliance on additional energy, such as natural gas.

For more information about how heat exchangers help improve food and beverage production, call Noren Thermal Solutions in Taylor, TX, at 866-936-6736.